Fact File:Everything you need to know about Carbon Nanotube

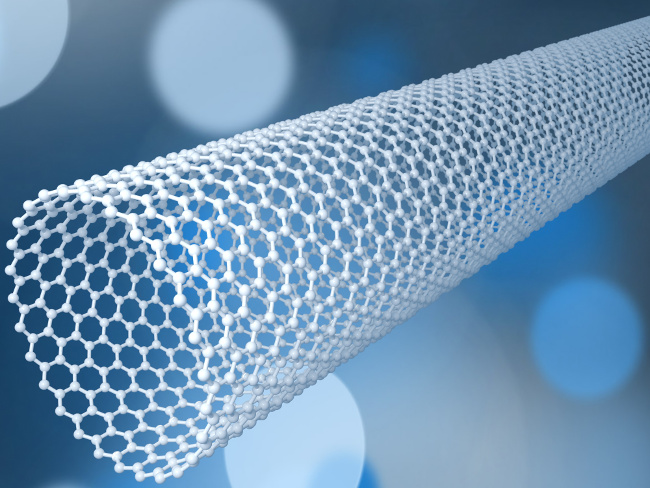

Rather than being a physical tube, such as a drinking straw or a gas pipe, a Nanotube is a material of nanoscale proportions that has a tube-like structure. When you look at Nanotubes with the naked eye, you shouldn’t expect to see tubes; instead, you will see a material which looks more like black soot, or a powder. However, that doesn’t mean that nanotubes aren’t cylindrical structures. They are indeed rolled-up sheets of Graphene, and the walls that make up the structure are only one atom thick!

A nanotube can be made from a range of materials such as Carbon, Boron, and Silicon, but today we are going to focus on Carbon. Our fact file leaves no stone unturned, and hopefully solves any nanotube-related mysteries you may have.

Carbon Nanotube properties

The exceptional properties of Carbon Nanotubes have been discovered during thorough testing and experimentation. These special properties include high thermal conductivity, high electrical conductivity, elasticity with around 18% elongation before failure, flexibility, very high strength, and low thermal expansion. They are also excellent electron field emitters.

Carbon Nanotube structure

The structure of Nanotubes can be identified through their number of concentric cylinders, the radius of the cylinders, and the length of the cylinders.

Carbon Nanotube uses

Due to their remarkable electronic and mechanical properties, Carbon Nanotubes are among the best candidate materials for use in industrial applications. Here are some examples of current and potential uses for Carbon Nanotubes:

- Scanning probe instruments

- Field emission displays

- Energy storage

- Conductive adhesives

- Molecular electronics

- Structural applications

- Air and water filtration

- Thermal conductivity

- Catalyst supports

- Biomedical applications

- Fibres and fabrics

- Thermal materials

Production methods

There are several different methods of producing Carbon Nanotubes, some more common than others. Here are some examples:

- The Carbon arc discharge method – initially used in the production of C60 Fullerenes, this is the most common and possibly the easiest method thanks to its simplicity.

- Laser methods – laser vaporisation of Graphite rods with a 50:50 catalyst mixture of Cobalt and Nickel is followed by heat treatment in a vacuum to remove the C60 and other Fullerenes.

- Catalysed chemical vapour deposition – the most common method uses catalysed chemical vapour deposition of hydrocarbons over a metal catalyst.

- Ball milling – a simple method of placing Graphite powder into a Stainless Steel container with four Steel balls. The container is purged, and Argon introduced. The milling continues for 150 hours.

Other Carbon Nanotube synthesis methods:

- Diffused flame synthesis

- Electrolysis

- Use of solar energy

- Heat treatment of a Polymer

- Low-temperature solid pyrolysis

History of Carbon Nanotubes

Technically, Carbon Nanotubes can be traced back as far as 1959, when a researcher named Roger Bacon produced images of them. Then in the 1980s, Howard Tennant applied for a patent for a method of producing them. However, it wasn’t until 1991 that Sumio lijima not only took photos of them, but also put a name to them whilst being able to explain what they are. The first Nanotubes to be observed were those of a multi-walled nature. It wasn’t until two years later that a team, including lijima, synthesized single-walled Carbon Nanotubes.

3D printing Carbon Nanotubes

There is an exciting future for the partnership of 3D printing and Carbon Nanotubes. They have already been successfully used to 3D print shape memory Polymer to be used in soft robotics. Carbon Nanotubes’ research and discoveries are still ongoing and the opportunities for 3D printing are endless, from 3D miniature sensors construction to more complex aerospace parts.

Electrical conductivity

Carbon Nanotubes have garnered particular interest due to their conductive ability, making them a highly attractive option for numerous applications. Interestingly, the direction and the radius in which Graphene sheet is rolled up to form the Nanotube can also determine the electrical properties.

Armchair Nanotubes (named due to the armchair-like shape the edges make) share electrical conductivity properties like metals, unlike Zigzag Nanotubes, which are only semiconductors.

Carbon Nanotubes strength

Carbon Nanotubes are among the strongest materials ever discovered!

There aren’t many materials around that are 100 times stronger than Steel, yet still lighter than Aluminium. Currently, Carbon Nanotubes are used to enhance properties of other materials. For example, they are being added to Polymer matrices in order to improve their strength as well as their electrical and thermal conductivity. But why are they so strong? The answer to that question is twofold. First, their strength is provided by interlocking Carbon-to-Carbon covalent bonds. Second, each Carbon Nanotube is one large molecule composed of millions of atoms, which theoretically means there are no weak spots.

To learn more, talk to a member of the Goodfellow team today.